KOMET vacuum packaging machines as ESD version

Vacuum packaging machines in ESD design – the optimal solution for demanding environments where electrostatic discharges must be avoided. Our high-quality machines are equipped with a stainless steel housing that is not only robust but also provides excellent conductivity for electrostatic charges, thus ensuring effective ESD protection.

The vacuum packaging machines have dissipative feet or rollers that ensure safe dissipation of electrostatic energy. This is especially important in environments where sensitive electronic components need to be protected from damage caused by electrostatic discharge. The dissipative inserts and the dissipative lid complete the system and ensure continuous dissipation of static charge.

The vacuum packaging machines are the perfect complement to our EPApack film bags. Together, they provide a comprehensive solution for the safe packaging of sensitive products in ESD-controlled environments..

Advantages at a glance

- Made in Germany

- High-quality stainless steel housing

- Chamber device

- High-performance vacuum pump

- Reinforced transformer for ESD bags

- Fumigation device for nitrogen

- Vacuum stop button

- Inserts for height adjustment

- Domed plexiglass lid

- Soft ventilation

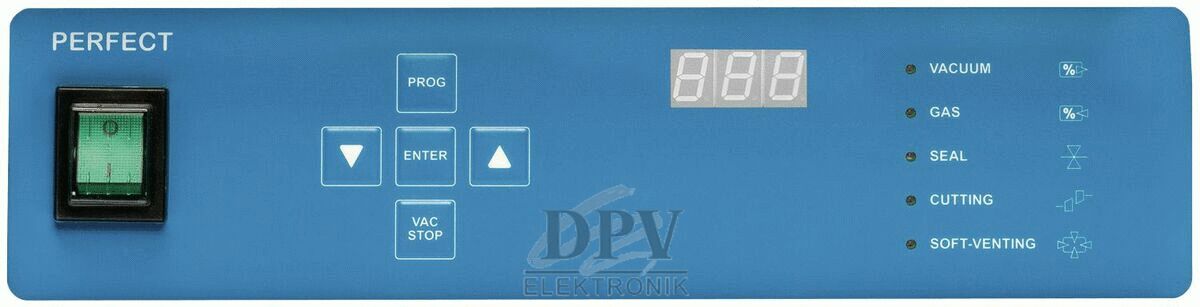

PerfectPlus-control

Sensor-controlled electronics for constant and reproducible vacuum – regardless of product and chamber size. Vacuum stop button. Welding times adjustable. 10 user programs can be stored individually. Standard with service program for dehumidifying the vacuum pump, boiling point detection, oil change indicator, soft ventilation and operating hours meter, password protection and separation welding with one temperature. Multi-cycle vacuum and gassing can be activated.

Special features of the ESD version

- Stainless steel housing

- dissipative inserts

- dissipative lid

- dissipative feet (EPAvacuboy and EPAplusVac20)

- dissipative castors (EPAplusVac24)

Further specifications

Nitrogen fumigation is used in vacuum sealers to reduce the oxygen content in the packaging. By fumigating with nitrogen, the oxygen content in the packaging is reduced to a minimum, e.g. oxidation. Nitrogen fumigation can be added during the vacuum sealing process if required. The gas is introduced into the packaging before it is sealed.

As a result, the oxygen is displaced from the packaging and replaced by nitrogen.

The reproducibility of the vacuum is critical, especially in the low range, to ensure that each component is packaged consistently and reliably. This consistency is particularly important in technical packaging, regardless of whether it is a high or low vacuum.

Precise and accurate adjustment of the vacuum is possible. Conventional machines often use a timer where the time runs out, but without precise information about the degree of vacuum in the bag. For this reason, a sensor has been integrated into the Perfect controller, which is always consistent and performs all measurements extremely accurately and precisely.

By implementing the multi-cycle vacuum/gas system, an even cleaner environment in the packaging can be achieved. This means that it is possible to repeat the vacuum/gas cycle on the controller to ultimately obtain an even cleaner medium in the bag..

The vacuum bag protects the product from the outside against environmental influences (dust, dirt, moisture, etc.).

Permanent storage is possible because the product is protected from damage in the hermetically sealed vacuum bag, i.e. it is sealed so airtight that no gas, especially air, can enter or escape in the long term.

Our products

EPA®vacuboy

The tabletop device EPA®vacuboy is the perfect entry-level device. It is ideal for safe vacuum packaging of highly sensitive and sensitive electronic components. Compact tabletop chamber units enable a reliable vacuuming process without a large structure. High-performance vacuum pumps, in conjunction with the PerfectPlus control system, ensure a fast, consistent and reproducible vacuum..

EPA®plusVac20

EPAplusVac20 is ideally suited for the safe vacuum packaging of larger products, especially highly sensitive and sensitive electronic components. With ESD film bags, e.g. DPV-1000, you are on the safe side when it comes to ESD protection. The compact table-top chamber unit enables a reliable vacuuming process without a large structure. High-performance vacuum pumps, in conjunction with the PerfectPlus control system, ensure a fast, consistent and reproducible vacuum.

EPA®plusVac24

The EPAplusVac24 floor-standing unit is perfect for the safe vacuum packaging of larger products as well as for the simultaneous packaging of numerous small bags. With ESD film bags, e.g. DPV-1000, you are on the safe side when it comes to ESD protection. Robust and compact free-standing unit is suitable for every application. High-performance vacuum pumps, in conjunction with the PerfectPlus control system, ensure a fast, consistent and reproducible vacuum.

Technical data

EPA®vacuboy  | EPA®plusVac20  | EPA®plusVac24  | |

Camber size W x L x H | 360 x 380 x 140 mm | 430 x 505 x 175 mm | 640 x 480 x 200 mm |

Sealing length | 350 mm | 1 x 405 mm | 2 x 455 mm |

Sealing jaw | front | front | right and left |

Pump | 10 cbm/h | 21 cbm/h | 60 cbm/h |

Power supply | 230 V / 1 Ph+N+PE/50 Hz | 230 V / 1 Ph+N+PE/50 Hz | 400 V / 3 Ph+N+PE/50 Hz |

Power | 0,7 kW | 1,1 kW | 1,9 kW |

Max. bag size | 350 x 400 mm | 400 x 500 mm | 450 x 600 mm |

External dimensions W x D x H closed lid | 410 x 500 x 360 mm | 480 x 655 x 385 mm | 710 x 665 x 1.010 mm |

Height open lid | 760 mm | 920 mm | 1500 mm |

Weight | 44 kg | 62 kg | 117 kg |

Workwear | Professional Footwear 2024

Workwear | Professional Footwear 2024 DPV main catalog 2023 | 2024

DPV main catalog 2023 | 2024